|

Fabrication of nanostructured materials and surfaces Materials are fabricated by physical vapour deposition techniques suc as Pulsed Laser Deposition (PLD) in a bottom-up approach. Materials are designed and synthsized for different applications such as:

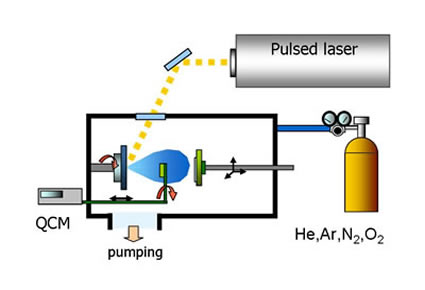

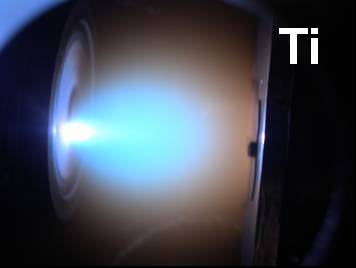

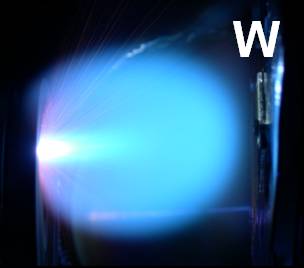

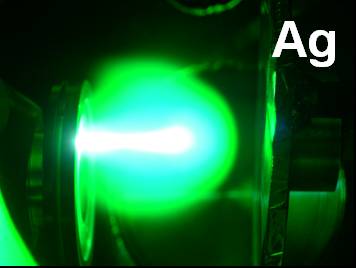

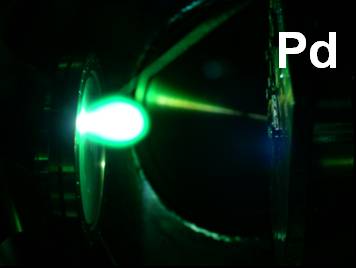

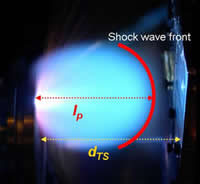

In PLD technique a target material is locally vaporized by high power laser pulses. The species emitted from the target surface form a plasma plume and can condense on a substrate and form a film. The main advantages of this technique are the flexibility in material deposition (isolants, ceramic, polymers) even with complex stoichiometry materials. Varying the plume expansion dynamics clusters and nanoparticles with different size and kinetic energies can be produced. This opens the possibility to grow films (from compact to porous) with controled properties (morphology, porosity, cristallinity, composition).

|

|

|